Dedicated readers will note I often share my mistakes. I do so for many reasons, not the least to keep me humble. I believe sharing one's flaws is a sign of strength, not weakness. (Although so often shared, one might think I always fumble my way through builds. And, dear reader, you are not wrong.) So here is yet another.

Perhaps you'll find it comforting; we all make mistakes. Or even a little funny? Whatever you take away from this, I am glad you are here reading along. ~JRC

One area where I unfailingly prepare is shop safety. Always. But there are many other tasks where I don’t take the time, or misplace my thinking cap, and create blunder after blunder. Mistakes like these are not inevitable and could be avoided with enough care and advanced planning. Much like being safe. But mistakes are still part of the game because we’re all human - and inherently fallible.

Thankfully, many such errors are quickly realized and relatively easy to remedy. "Darn. I cut that one inch too short." Or, "I drilled that hole off center." These and other minor mistakes can be frustrating but are readily fixed with a new piece, a fresh cut, and a deep breath.

But then there are the mistakes that happen several steps back, causing a series of problems thereafter. Minor errors in and of themselves take on a whole new level of complexity once buried deep within a build. And depending on how far one gets before noticing, hours and dollar signs begin adding up. Such mistakes are often called compounding errors. But in a build that is otherwise spot on, I tend to refer to them as a perfect wrong.

This week, I did a perfect wrong, leading me to share today's story.

I am building a rather elaborate side project with multiple steps, using many fabrication techniques. It's a mini travel camper, and I will share a lengthy "reveal" on this build soon. But for now, let me share my blunder.

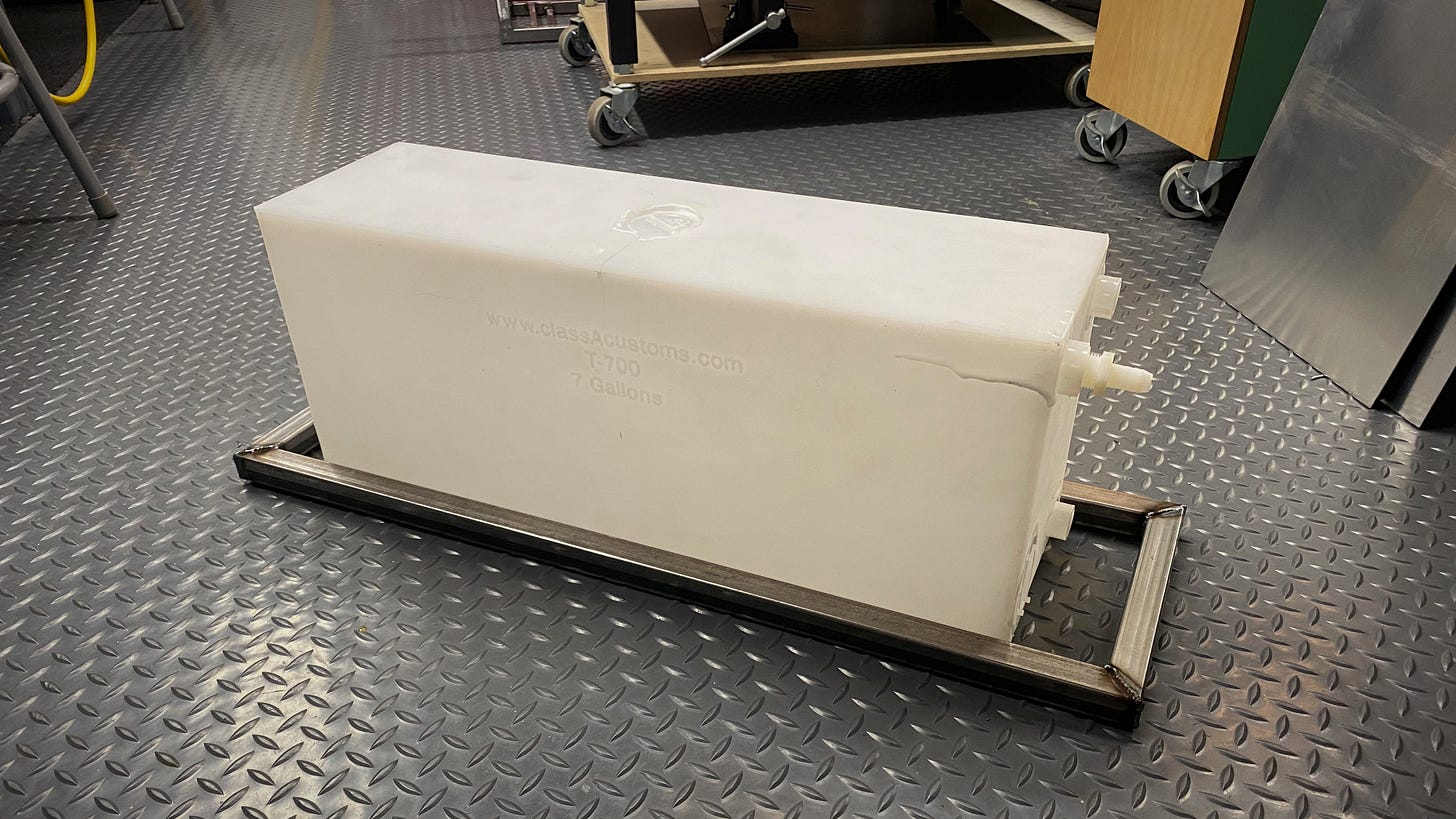

One step required I construct a steel cage to support a sizeable shoebox-shaped water tank. The tank goes under the trailer, so I need the tank's narrowest dimension aligned perpendicular to the trailer deck (for ground clearance). Anyway, I am nearing completion of the whole project that's dragged on for far too long, and I was regrettably in a hurry.

See where this is going?

I'm using my favorite steel for the cage, 1"x1" 16 gauge square tube, and I comfortably know how to weld it using my now-trusty MIG welder. I've also gotten comfortable with sizing and cutting this steel, so the job was going swimmingly, or so I thought. It wasn't until I fit the bottom rectangle to the tank to make the subsequent measurements that I recognized the error in my ways.

Instead of having the narrowest dimension as the height, I designed the cage to fit the tank on its side. (Imagine taking a shoe box and tilting it up, making the box stand taller.) Adding insult to injury, I went far beyond tack welding all the joints and instead moved on to making the final, solid welds for each.

It was an acceptable job, and I was happy about the work. Each weld was rather neatly done (given my still-rather-novice abilities in this art), and the shape was dead-on square. But one minor-now-major mistake glared back at me. That being the size.

At this stage, it was basically a complete do-over.

This silly mistake shouldn’t have happened, but it did.

I've been belaboring about how to build this cage for weeks now. It's my design, and I haven't seen anything like it. So I put a lot of thought into designing it, knowing that it would be a rather tricky assembly requiring exact dimensions.

When I started cutting metal and welding the cage together, I thought I had everything planned. And I did. But instead of jumping in fresh and clear-headed, I started early in the morning with a cloudy mind not yet stimulated clear by caffeine.

Whatever lapse in cognitive ability manifested that day, it didn't impair my metal work. As mentioned, I did a nice job. But I simply made the cage right - for the wrong dimension.

A perfect wrong if there ever was one.

I thought about cutting the cage apart and reusing the steel. But it so frustrated me that I couldn't, in the moment, deal with the added mess and work. So I set it aside and cut and welded new lengths.

All worked out well once I adjusted my frame of mind and re-framed the cage as imagined.

As for the cast-aside other, I could easily find a new use for the steel at some point. But, instead, I might keep it around as a reminder of my folly. Much like these self-deprecating stories, a few discards around the shop are helpful. They remind us of what can go wrong. And keep us striving to do better.

But when we don't, when we don’t do better and instead allow a perfect wrong to slip again into our maker path, hopefully, we can shrug it off and move on as I did with this one. Maybe we’ll even laugh it off next time.

Yes, laugh it off. Those builds that are spot-on in every way...except.

Until next time.

JRC

Perfect Wrongs were common in manufacturing before several innovations in assembly philosophy were introduced. An error early on that remained or propagated through the rest of assembly, only to be discovered at final QC, led to costly rework and waste.

But to a maker or entrepreneur, a Perfect Wrong is anything but something to be ashamed of. Quite the contrary…they are often viewed as a badge of honor. Part of the learning process. What not to do next time. One of Edison’s many ways “not to build a light bulb.”

My favorite wrong is one with a specific name in German: Schlimbesserung. In English it takes a few words to explain, but the concept is recognizable to almost everyone: “an improvement that makes things worse.”

And as you do, John, I keep examples of my wrongs around for good measure. And they also make great stories! :-)