My top maker materials: 1/4-inch baltic birch plywood

Part 2 of a limited series

Today, I discuss my go-to laminated wood product of choice. You'll need quite a few tools plus practical experience to use today's featured maker material, so I imagine this one's not for everyone. But stay tuned! Next week's installment is something almost anyone can make with, and chances are it's already in your shop or home. ~JRC

Today's featured material: 1/4-inch baltic birch plywood (and, to a lesser extent, both its thinner and thicker brethren)

Tools I use: table saw, circular saw, router, and various other woodworking tools.

Cost of entry: $250 to over $3000 for a table saw, depending on make, model, and options. One can get by with a circular saw ($50 to $200) and straight edge, but the work can be time-consuming. Other woodworking tools needed include a router, drill, sander, nailer, and other miscellanies, totaling $300 or more. The 1/4-inch baltic birch plywood costs about $35 for a 5-foot by 5-foot sheet.

If steel is king, then plywood is queen. ~Tom Sachs

Plywood is nothing short of an engineering marvel.

Made of thin wood veneers, or "plies," plywood comes in large, uniform sheets suitable for various applications, from siding a building to handcrafting furniture. The veneers are sliced off in continuous sheets from whole logs (imagine unrolling a roll of paper towels) and then glued together "cross-grained," meaning the wood grain alternates between sheets giving plywood its uniformity and strength. There are many grades of plywood, depending on the species of wood used, the quality of that wood, and the number of layers.

The cheapest plywood is rough, made of few plies, full of voids within plies, and littered with knot holes. While it has its place, mainly in general construction and boarding up windows before a storm, this plywood is not that which I praise. No, the stuff I am concerned with here is the good stuff - baltic birch.

As the name indicates, baltic birch plywood is made from any number of fast-growing hardwood birch species (Betula sp.), historically harvested in the Baltic region, including Finland, Russia, and other countries along the Baltic Sea. The wood is uniform and strong, making it amenable to high-quality plywood manufacturing. Today, it's farmed in many regions around the globe, offering a high-yield, renewable maker resource. Bonus: many plywoods are from wood harvested sustainably and, today, use little to no toxic glues, making them better for the planet and safer for us.

Baltic birch plywood has numerous thin, homogeneous layers creating exceptionally flat and robust sheets. It comes in many standard thicknesses, from 1/8-inch to over 1-inch, with layers ranging from five to eleven or even more. My Baltic birch plywood of choice is 1/4-inch with five layers.

While I use various thicknesses of baltic birch plywood, depending on the application, I most often gravitate towards the 1/4-inch stuff because of its unparalleled strength-to-weight ratio. At less than a pound per square foot, an entire five-by-five sheet is easily handled by one person (and I'm a one-man-show in my shop). I often have my supplier rip the sheets in half for even easier handling and storage.

On various creator channels on YouTube and in many project plans calling for baltic birch plywood, makers often recommend 1/2-inch or thicker sheets. I believe they do so partly because the thicker sheets are flatter than the 1/4-inch. But these thicker sheets are usually overkill, in my experience.

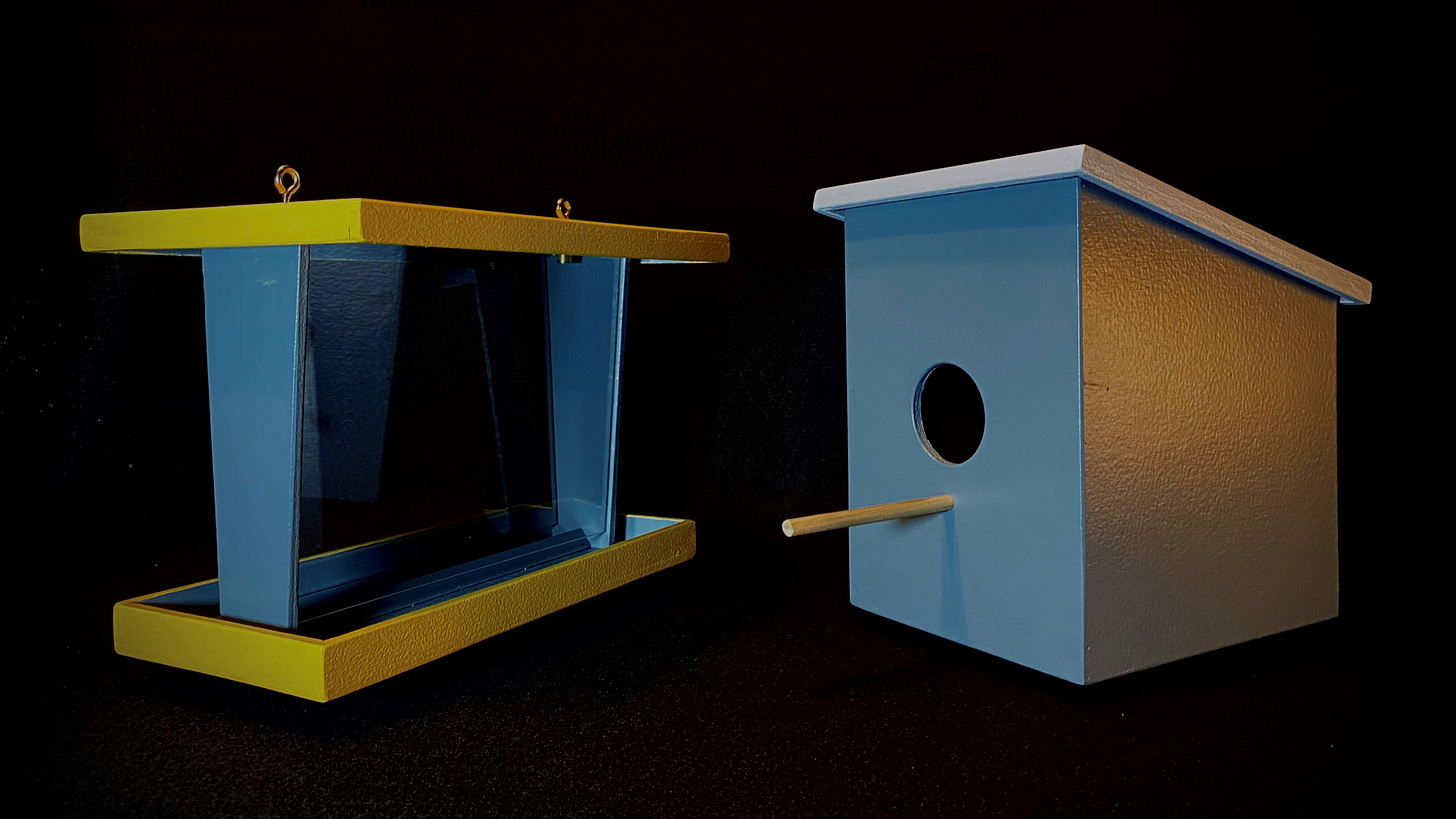

The 1/4-inch stuff works exceptionally well for small projects like drawers and boxes, creating more usable space with literally half the weight of half-inch plywood. It's true that in whole sheets, the 1/4-inch plywood flexes and warps somewhat, but as long as it's applied to an appropriate frame or sub-structure to flatten it out, the thinner sheets work well for larger projects too.

Sizing 1/4-inch baltic birch plywood is a piece of cake on the table saw. It's manageable to manipulate because it's so light, and a sufficiently sharp blade easily cuts through it. But doing so is not worry-free, by far.

WARNING: LENGTHY SEGMENT ON TABLE SAW SAFETY AHEAD.

The safest way to use a table saw is NOT to use a table saw.

But if you must, it has to be done with absolute vigilance, respect for the tool, and a healthy dose of fear. Every. Single. Time.

Table saw dangers are many, including the obvious risk of that spinning blade mere inches away from one's fleshy digits. Another less apparent risk is known as "kickback." Kickback occurs when wood tilts into the blade or binds between the blade and fence, causing the wood to fly back violently toward the user. Kickback happens so fast and with such force that victims are often impaled or even killed outright. This is not hyperbole, as President Biden is fond of saying.

Take care to know the table saw, get proper instruction before ever using one, and always be prepared for the unexpected. And, of course, never modify a table saw, and do not remove the safety features.

I have an older Jet 10 inch saw, a real gem. Honestly, I think it's my most favorite tool in my entire shop. But I fear it as much as Death itself. I never, ever casually flip on its switch and begin to cut. Instead, I first don all the appropriate PPE, then size up my project at least twice, triple-check my surroundings to make sure I have room to complete the cut, and then - only then - do I proceed.

As much as I love my Jet, it lacks some protections on newer saws. If I were in the market for a new one, I'd go with a SawStop brand table saw. These are the ones that have an integrated sensor that detects flesh contact with the blade, causing an immediate stop to the system. What usually would end in a life-changing injury results in nothing a Band-Aid won't fix.

SawStop table saws detect flesh through the electrical disparity between wood and hand and throw an aluminum “brake” into the blade, halting everything immediately when contacting the latter. If you haven’t seen it, look online for a demonstration video; it's a dramatic stop. The brake and blade need replacing after the event. But parts are cheap compared to the alternative.

Speaking of cost, did I mention SawStop saws are way expensive? Plan on shelling out $3500 for a basic shop model. Well worth it, I would say.

Now back to the maker material review.

After sizing 1/4-inch baltic birch plywood, I like to join it in various ways, including glues, nails, screws, and sometimes specialty joints.

Cyanoacrylate (CA) glue ("super glue") works quite well on baltic birch plywood, and for smaller quick builds, I often use it along with a shot of activator to lock in pieces quickly.

For added strength, I have a 23-gauge pneumatic nail gun I often reach for. This tool inserts tiny nails precisely, making joinery with thin plywood a breeze. For larger projects, I often pre-drill holes with a counter sink and use wood screws, often combined with wood glue.

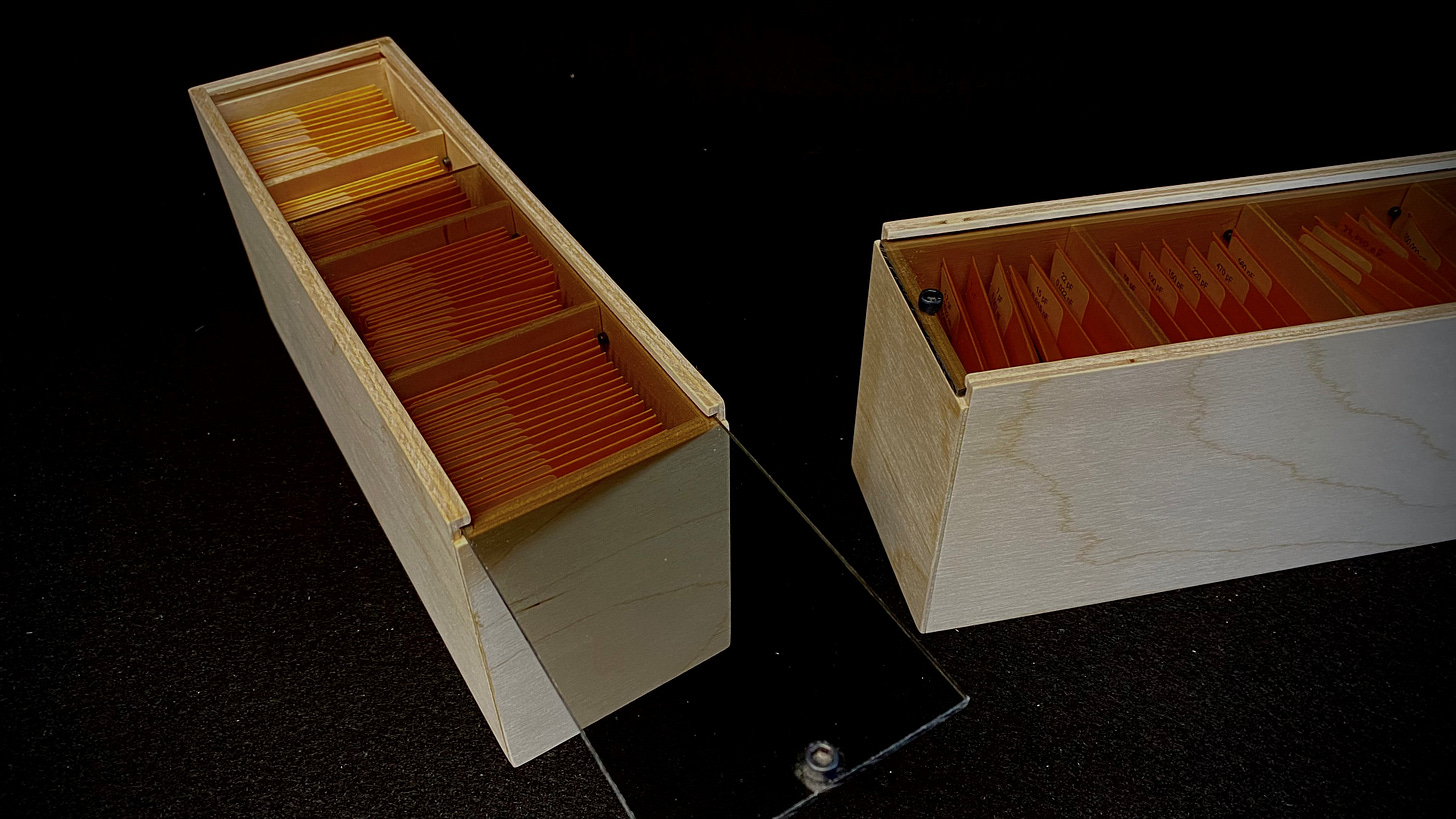

While butt joints work fine with 1/4-inch baltic birch plywood, other specialty joints work even better. Think dovetails and the like. My favorite is the rabbet joint, where a groove the same width as the plywood is cut along one edge so that the other piece joins the former at a right angle.

This joint creates two planes of contact, enhancing strength and stability. Quick and easy to make, rabbet joints are an excellent way to connect pieces.

Finishing baltic birch plywood is also relatively easy, owing to its clean surface and fine grain. The sheets look great simply sanded and then lightly oiled or waxed, but they also accept stains and paint well.

As an underlayment, this high-grade plywood is a bit overkill. Still, if you want a superior surface to laminate other materials onto, like Formica sheets or aluminum, baltic birch plywood will not disappoint.

Many makers hide the edges of plywood when building furniture and similar projects. But I love the engineered edge, particularly on baltic birch with all its clean layers. I’ve built numerous projects where the plywood edge is plainly visible and even featured. The look is industrial chic, kind of like an Eames chair or the interior design of a Chipotle (say what you want about their burritos, but I do appreciate the minimalist plywood-forward decor). Still, if you conceal the plywood edges to make more traditional-looking builds, the final look can be quite polished, rivaling even all-hardwood designs.

There you have it, the skinny on why 1/4-inch baltic birch plywood is among my top maker materials.

As with woodworking in general, you'll need quite a few expensive tools to use this high-grade plywood effectively. But the sheets themselves are economical, particularly given their versatility and durability. Whatever you end up making with it will be several steps above anything created with lesser plywoods.

Do be careful, as already mentioned. The table saw, a near must-have for sizing plywood, is no joke and can quickly turn a weekend project into a horror show. But with the proper care and attention to detail, working with 1/4-inch baltic birch is one of the great pleasures of making.

Until next time.

JRC

I am really liking this series - someday I am going to have a workshop!

Baltic Birch is so beautiful ! I want to be a wood worker !