Make it with Cardboard!

Re-sharing "My top maker materials: Corrugated Cardboard"

This Halloween season, I often reach for corrugated cardboard in my makeshift designs. And why not? The stuff is super useful, easy to work with, and readily available. Have a read through this post if you’re looking for a quick design method - with an emphasis on “quick.” Halloween is only a day away! ~JRC

My top maker materials: Corrugated Cardboard

First published May 1st, 2023

Today's featured material: corrugated cardboard

Tools I use: hobby (X-Acto) knife, utility knife, straight edge, various types of glue, tapes, and paints.

Cost of entry: Much less than $50 for a suite of tools useful in cardboard creations (most of which you probably already have). New corrugated cardboard can be purchased in large, untouched sheets for very little (e.g., 4-foot by 4-foot sheets run about $2 each). But why buy new when so much of it is free for the taking?

Cardboard is another material that's ubiquitous, and everybody hates, yet when I made furniture with it, everybody loved it. ~Frank Gehry

Corrugated cardboard. Also known as corrugated fiberboard or simply "cardboard," it is an engineered paper product consisting of a fluted corrugated inner layer of kraft containerboard with one or two flat outer layers. Invented in the late 1800s, corrugated cardboard today is used in various applications, most notably in the packing and shipping industries.

The design creates a remarkably sturdy but light material owing to the corrugations inside. Multiple sheets of corrugated cardboard become exceptionally strong when layered. Doing so provides a cost-effective reinforcement for heavy items in shipping, among other applications.

Much like plywood, corrugated cardboard comes in various grades. The overall characteristics (and use) depend on the thickness of the fiberboard employed, the number of flutes per area, and the kinds and amounts of adhesives applied. Qualities measured include moisture content, crush strength, bursting strength, and impact and tear resistance. While these specifics are not commonly known, we've all encountered "heavy-duty" cardboard vs. the lightweight stuff.

Cardboard is often a side consideration, if that. It's the stuff our shiny new "whatever" just came in, and we cut through it as fast as possible to get to the good stuff inside. Occasionally, something will come in a relatively convenient and sturdy corrugated cardboard box, which we keep to store other random material collections around our shops and homes.

As for making with corrugated cardboard, such creating is often children's work. Cardboard is freely available to many young makers, and working with it is easy and safe - no dangerous power tools are required. One of my many fond memories from childhood involved an extra large corrugated box our first new refrigerator came in. That thing was huge and served as the ubiquitous childhood fort for several days if not weeks.

Most makers, I among them, tend to grow out of using corrugated cardboard in favor of more robust and seemingly legitimate maker materials like wood, plastic, and metal. But corrugated cardboard has a place in even the most advanced maker's space. I've come to relish a good sheet of corrugated cardboard and squirrel the stuff away for any number of applications.

As mentioned, one quite obvious use is to store other stuff. But this isn't making. I'm concerned with taking good sheets of cardboard and using them to create new things. Templates and models are two of the most common items I make with corrugated cardboard.

Templates are helpful when making more than one thing of a given shape. Cardboard cuts easily in various forms, so making a template helps a maker see what a shape will look like at actual size and affords an effective means to trace that size onto wood, for example.

Similarly, corrugated cardboard makes a near-perfect material for assembling scaled or full-sized design models before making the creation in a more permanent material.

I recently needed to make several curved plywood cuts with a 12" radius, but I wasn't sure if that size was right for the project. So I made a cardboard model to look at it first. And a few years ago, I made a more elaborate corrugated cardboard model of the Evil Dead chainsaw prop I created for my son one Halloween. I was scaling the chainsaw down in my design to look proportional to a kid's costume. Unsure of scaling calculations, I first created a corrugated cardboard model to confirm.

Sometimes making with corrugated cardboard is not a prelude to something else but is the primary material for a finished design. Many costumes I've made from the stuff, often embellished with other materials like colored paper or duct tape. Because of its strength and minimal weight, corrugated cardboard is perfect for these [often] last-minute designs.

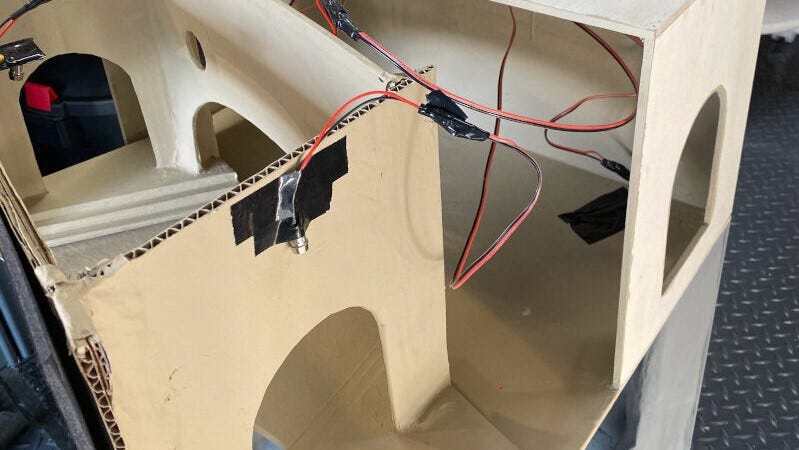

I've also used corrugated cardboard in more refined constructions. For example, I fashioned the inner walls on a scale Jabba the Hutt's Palace diorama using it, coating the cardboard with layers of paper mache.

The result looked much like stone, belying the humble material hidden inside.

Compared to more elaborate uses, my work with corrugated cardboard is still admittedly rather basic. Many artists and designers have taken the material to extraordinary heights, ranging from intricate fine furniture to whole buildings.

Honestly, the uses seem endless when designing and making with corrugated cardboard.

Regardless of what you make with it, there are a few essential tools and methods useful in corrugated cardboard construction. Scissors work for thinner and weaker sheets, but a good hobby knife and utility knife are preferred. I like to use an X-Acto when cutting free-hand shapes as the narrow blade turns easily in the material, allowing one to almost "draw" whatever shape desired. I prefer a sturdy utility knife for straight cuts; the thicker blade holds true along a straight edge better than a hobby knife blade.

In making corrugated cardboard parts, it's essential to consider what direction the corrugations are in and design around these appropriately. Corrugated cardboard easily folds with the pleats but maintains its shape better at 90-degree angles to them. For added strength, make two or more parts the same shape, alternating the direction of the pleats for each, and laminate these together.

Holes are easy to cut in corrugated cardboard using a dedicated hole cutter or even step drills. The latter will shred the edges a bit, so not a good choice for anything that will show. But still, if you need to bore through some sheets, don't hesitate to pull out the drill and bits.

Joining corrugated cardboard parts is readily done with glue or tape but is also possible with mechanical fasteners like nuts and bolts, or screws.

Duct tape works very well for rougher or quick designs, as does regular masking tape - these two I often employ for models and templates. But for a superior bond and a more finished look, reach for the white glue. This adhesive works exceptionally well on corrugated cardboard; the paper will rip before the bond fails. (Note: I've used CA "super" glue occasionally, but it seems to penetrate poorly in the fiberboard, making a weak connection.)

Moving parts in costumes, as well as structural designs with corrugated cardboard, require mechanical fasteners and joints. The material takes bolts and screws well, much like plywood, although the paper will rip with too much force, so keep that in mind. I'm considering a rather large and elaborate costume for this coming Halloween, involving several moving parts. If I give it a shot, it'll take various bolts and nuts to pull it together, so stay tuned for an update on how well this works.

That's it for this installment on my favorite maker materials. When designing your next project, I hope you give corrugated cardboard a second look. This everyday stuff is far more than box material. From templates to models to the finished design - corrugated cardboard is maker material, worthy of a top spot among coveted materials of all kinds.

Until next time.

JRC